CONTI SYNCHRORIB Combined Belts for Specific Applications

An excellent alternative to the significantly more expensive double-sided timing belts is now available for inquiry in the Eshop.

- Basic Information

- Characteristics

- Profile and Dimensions

- Belt Construction

- Modern Mills and Power Transmission

CONTI SYNCHRORIB Belts

One side of the belt is composed of a timing belt (SYNCHRO), while the other side features a poly-V-belt (RIB). The timing belt ensures precise, synchronous movement, whereas the ribbed side permits minor slippage.

These belts were specifically designed for mill table roller drives. This is because double-sided timing belts often suffered damage due to overloading and shocks.

CONTI SYNCHRORIB Combined Belts in the TYMA CZ Eshop

Inquire about the belts via the inquiry form provided here. Then we will contact you and, if necessary, specify all the technical parameters and tell you the price of a specific product.

CONTI SYNCHRORIB Belts Characteristics

- Timing belts allowing minor slippage on the ribbed side

- Temperature range depending on application, from −20 °C to +100 °C

- Antistatic property according to ISO 9563

- Moderately oil resistant

- Ageing and ozone resistant

- Suitable for tropical climates

- Maintenance-free

- Low in PAHPolycyclic Aromatic Hydrocarbonss – category 2 according to AfPS-GS-2014-01-PAK (for CXP and CXA design)

Profile and Dimensions of Combined Belts

The toothed side of the belts can have either an HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. or STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. profile. The type of tension member used depends on the power to be transmitted. They are available with a glass cord tension member (STANDARD and CXP), or with an aramid tension member (CXA).

The ribbed side of the belt has a PK profile with a rib spacing of 3.56 mm. These are quite unique belts, produced in only a few specific lengths and widths, which are determined by the number of ribs.

Available Profiles and Length Ranges

| Profile | Belt Length (mm) |

|---|---|

| HTDHigh Torque Drive Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. 8M |

1760–2400 |

| STDSuper Torque Drive The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. S8M |

1552–2800 |

| HTDHigh Torque Drive Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. 14M * |

1778 |

* This profile is not included in the ContiTech product range for the CONTI SYNCHRORIB belt series. However, we can offer a product from another manufacturer.

CONTI SYNCHRORIB Belts Construction

The construction process of the belt begins by grinding a single-sided timing belt of specified dimensions until it is just above the tensile fibers.

Subsequently, a rubber backing is vulcanized onto this ground base. After the vulcanization process, the required number of PK profile grooves are ground into the rubber back.

- Polyamide fabric

- Synthetic rubber teeth

- Glass cord tension member for STANDARD or CXP (aramid tension member for CXA)

- Synthetic rubber ribs

Modern Mills and Power Transmission

The milling industry boasts centuries of history, with technology that is constantly evolving. While traditional mills utilized stones rotating against each other to crush grain, modern mills grind the grain into flour using a mill table.

Mill tables operate on the principle of rollers rotating against each other at varying speeds. The grain is gradually refined and ultimately crushed to the desired coarseness. The surface of the rollers can be either smooth or grooved, depending on the fineness required for the material being ground. The deeper the grooves, the coarser the resulting flour or scrap. Mill tables are more efficient than traditional grinding stones and can produce flour of a higher quality.

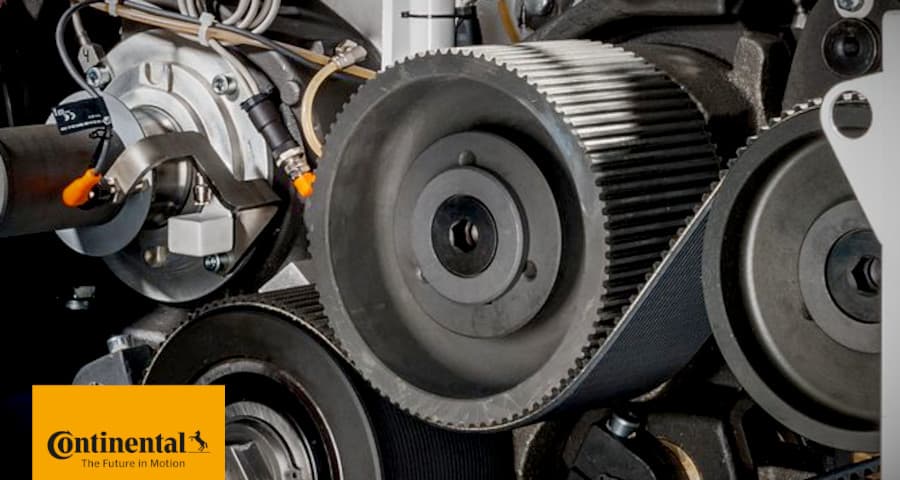

The rollers of the mill table are typically driven by an electric motor, which transmits power to the rollers via belts. The type of belt used depends on the specific characteristics of the machine. Some milling machines also employ gears, which are more robust and durable than belts, but also more expensive and noisier.

CONTI SYNCHRORIB combined belts are a reliable and economical choice for driving the grinding mill tables in a wide variety of mills.