High-Quality Roller Chains by KettenWulf. Clearly Explained

From standard DIN 8187 types through reinforced or corrosion-resistant variants, all the way to the premium TGI series. Our Eshop offering is now broader and more structured.

- KettenWulf KW – Above-Standard Standard

- KettenWulf HFS – High Fatigue Strength

- KettenWulf Chains That Do Not Rust? TGI! Or…

- KettenWulf LF – No Lubrication Needed. Lube-Free!

Different operations have different demands. Are mechanical properties, such as wear resistance and fatigue strength, critical to your application? Or is resistance to harsh environments your primary concern?

Some requirements complement each other, while others may conflict. Our chain portfolio is structured to offer optimal solutions for every application – from both a technical and an economic perspective.

Drive Roller Chains in the TYMA CZ Eshop

Looking for a chain suitable for continuous heavy-duty operation? Does it need to resist corrosion and withstand temperature fluctuations?

We offer both standard and specialized ranges of roller drive chains according to ISO 606, DIN 8187, and DIN 8188 (ASA/ANSI) standards.

Our Eshop categories clearly reflect each chain type’s key properties:

- Standard Roller Chains (According to DIN 8187)

- Corrosion-Resistant Roller Chains

- Reinforced Roller Chains

- Reinforced and Corrosion-Resistant Roller Chains

- Maintenance-Free Roller Chains

- Stainless Steel Roller Chains

- ASA/ANSI Roller Chains (According to DIN 8188)

KettenWulf roller chains distinguish themselves from standard chains with enhanced wear resistance and improved fatigue strength. That’s why they form the backbone of our product range – replacing KÖBO chains in this role.

Let's now take a closer look at the individual KettenWulf product series: standard KW, corrosion-resistant NP, reinforced HFS, reinforced corrosion-resistant TGI, maintenance-free LF, and stainless steel SS.

KettenWulf KW – Above-Standard Standard

KettenWulf KW chains represent an enhanced basic series of roller chains.

Thanks to carefully selected manufacturing methods and high-quality materials used for each component, these chains offer approximately 40–60% higher fatigue strength compared to the ISO 606 standard. Length tolerances during production range from 0 to 0.05%, whereas the standard allows up to 0.15%. They also demonstrate increased wear resistance, for example compared to the economy-grade ISON brand (also from KettenWulf).

The wax-like initial lubricant, applied in a hot bath, and the default preloading exceeding 40% of the chain's tensile strength, effectively reduce initial wear. KettenWulf roller chains' initial lubrication is suitable for operating temperatures ranging from −30 °C to +130 °C.

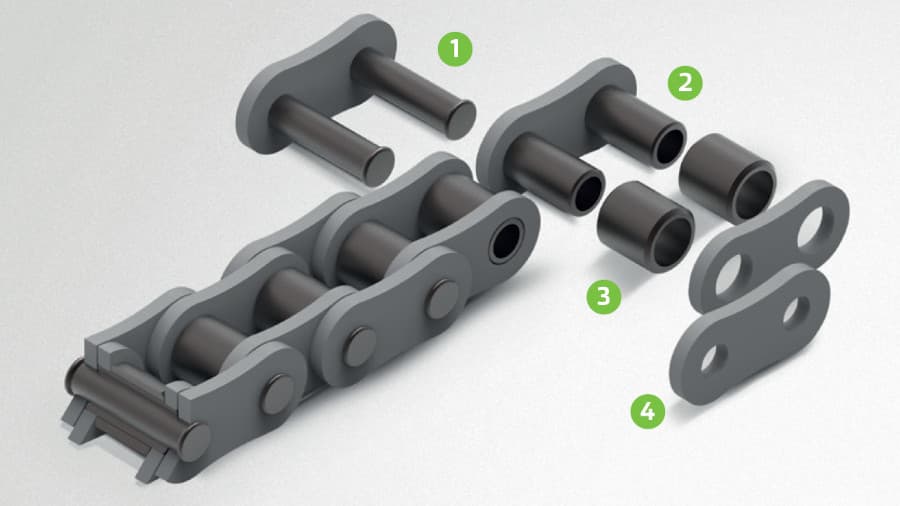

As mentioned earlier, a key factor is the precise manufacturing of the individual chain components:

-

Pins

Alloyed, case-hardened steel (up to size 1 1/2″) provides excellent shear strength and high core toughness. The precision-ground surface reduces friction between the pin and the bush. -

Bushes

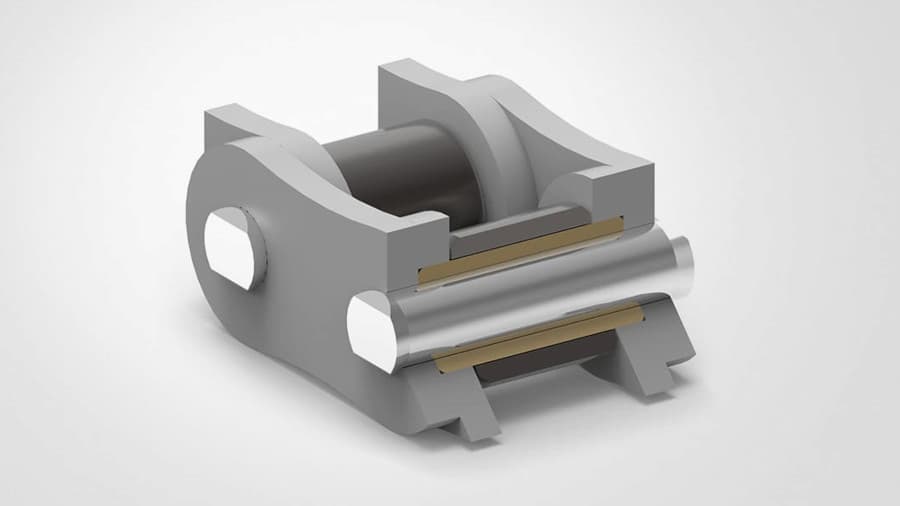

Seamless, cold-extruded bushes ensure a highly precise cylindrical shape – significantly better than bushes made from precision steel tubing. Surface-hardened steel further increases hardness and wear resistance. -

Rollers

Seamless rollers are surface-hardened (or fully hardened in sizes above 5/8″), enabling them to effectively absorb shock loads during sprocket engagement. -

Link Plates

Both inner and outer link plates are hardened, tempered, and subsequently shot-peened. High-precision punching with a high proportion of clean-cut edges and strict manufacturing tolerances contributes to the chain’s excellent overall fatigue strength.

KettenWulf KW chains are available as standard in all common types according to DIN 8187 (European B series) and DIN 8188 (American A series), in simplex, duplex, and triplex configurations.

Standard Roller Chains in the TYMA CZ Eshop

KettenWulf HFS – High Fatigue Strength

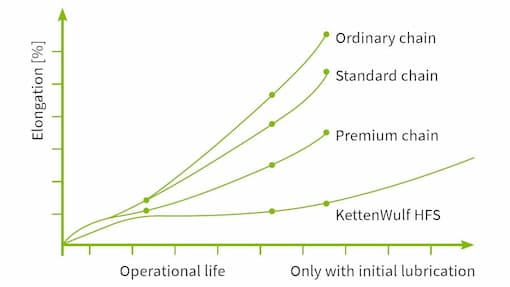

KettenWulf HFS roller chains are designed for applications with high loads and dynamic impacts. They rank among the top-performing chains on the market.

Thanks to targeted design and manufacturing enhancements, these roller chains significantly exceed the parameters of standard series. With precision punching of the link plates achieving hole straightness of up to 90%, they offer exceptionally strong press fits. The wider waist of the link plates further improves load distribution. As a result, HFS chains deliver approximately 15–20% higher fatigue strength compared to the KW series (equivalent to 70–80% above the ISO 606 standard), while maintaining excellent length accuracy.

Additional improvements in wear resistance come from using advanced materials for bushes and rollers. Solid bushes are made from alloyed case-hardening steel containing chromium, manganese, and molybdenum, ensuring high surface hardness and excellent resistance to friction and shock. Rollers made from structural C35 steel are fully hardened across all sizes.

KettenWulf HFS chains are available in types from 08B to 72B according to the DIN 8187 standard, with a slightly narrower size range available according to DIN 8188. They are offered in simplex, duplex, and triplex configurations.

Reinforced Roller Chains in the TYMA CZ Eshop

KettenWulf Chains That Do Not Rust? TGI! Or…

Harsh operating environments can be a serious challenge for power transmission components. Choosing the right chain means considering the nature and degree of exposure – along with other application parameters.

Corrosion-resistant chains are ideal for outdoor installations, high-humidity environments, and areas exposed to salts, chemicals, or extreme temperature changes. They are also well-suited for use in the food industry and other hygiene-sensitive operations, as well as applications with limited access for maintenance.

Several solutions are available, differing not only in price but especially in their balance between corrosion resistance and mechanical durability. For roller chains, KettenWulf applies three main approaches:

-

The stainless steel used in KettenWulf SS chains offers excellent protection against humidity, aggressive substances, and temperature extremes – making it ideal for food and chemical industries. However, the trade-off is lower mechanical strength and load capacity. Stainless steel chains are not hardened, and thus not suitable for high-load drives.

-

By contrast, nickel-plated KettenWulf NP chains offer significantly higher mechanical strength than stainless steel while still providing basic corrosion protection. They are ideal for less extreme conditions where surface protection of transmission components is still required.

-

Reinforced KettenWulf TGI chains combine the robust mechanical design of the HFS series with an advanced Geomet® coating, resisting over 500 hours in salt spray tests. The result is KettenWulf’s most corrosion-resistant chain, perfect even for demanding, lubrication-free operations.

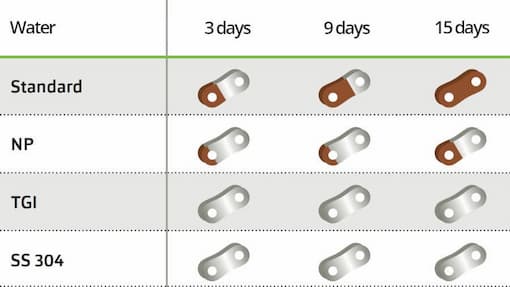

The table below illustrates differences in corrosion resistance when exposed to water. While standard and nickel-plated chains show visible rust within a few days, KettenWulf TGI and SS chains, on the contrary, maintain an intact surface even after more than two weeks.

A closer look at the construction of corrosion-resistant product series:

KettenWulf SS

All components of KettenWulf SS chains – pins, bushes, rollers, and plates – are made from stainless steel grade 1.4301 (AISI 304). They are suitable for both acidic and alkaline environments and offer a broader operating temperature range than conventional chains.

The chains are supplied with a dry surface (without initial lubrication). Upon request, they can be delivered with a food-grade lubricant compliant with FDA H1 and H2 standards.

KettenWulf SS chains are available in types 06B, 08B, 10B, 12B, and 16B according to DIN 8187, in simplex and duplex configurations; types 20B, 24B, and 32B are available in simplex only.

KettenWulf NP

Based on standard KW roller chains, all components are nickel-plated, with an additional copper underlayer that significantly enhances corrosion protection compared to conventional nickel plating. These chains contain no hexavalent chromium compounds and are not prone to hydrogen embrittlement, which could compromise their strength under long-term loading.

Chains are supplied pre-lubricated with the same high-quality initial lubricant as used on KW chains. Upon request, they can also be delivered with food-grade lubricants compliant with FDA H1 or H2 standards.

KettenWulf NP chains are available in types 08B, 10B, 12B, 16B, 20B, 24B, and 32B according to DIN 8187, in simplex configuration only.

Corrosion-Resistant Roller Chains in TYMA CZ Eshop

KettenWulf TGI

With their Tri Guard Inchromised protective coating, KettenWulf TGI chains represent the top tier in corrosion, wear, and fatigue resistance. They are designed for the most demanding and aggressive conditions.

The materials and manufacturing processes are identical to the HFS series, delivering equally high fatigue strength. Pins are additionally chromised to achieve an exceptionally hard, smooth surface (hardness > 800 HV). All components are then treated with a special Geomet® protective coating to ensure outstanding corrosion resistance.

Chains are pre-lubricated using a high-quality lubricant applied in a hot bath.

KettenWulf TGI chains are available in types 08B, 10B, 12B, 16B, 20B, 24B, and 32B according to DIN 8187, in both simplex and duplex configurations. Selected sizes are also available to DIN 8188 (simplex only).

Reinforced and Corrosion-Resistant Roller Chains in TYMA CZ Eshop

KettenWulf LF – No Lubrication Needed. Lube-Free!

KettenWulf LF series chains are designed for applications where lubrication is difficult, undesirable, or impossible. They combine long service life with maintenance-free operation.

They are particularly suited for applications with limited maintenance access or where lubricant contamination of the surrounding environment must be avoided – such as food processing, pharmaceuticals, paint shops, or packaging lines.

The key design feature is a special sintered bush impregnated with lubricant, which releases oil only under increased friction and heat. This ensures that lubricant reaches exactly where it is needed – and only when necessary. To provide the required corrosion resistance, all components are nickel-plated. The operating temperature range is from −30 °C up to +160 °C. Higher temperature variants can be supplied upon request.

For even higher load capacity and environmental resistance, maintenance-free chains based on the reinforced TGI series are also available.

KettenWulf LF chains are available in types from 08B to 32B according to DIN 8187, in simplex and duplex configurations; size 20B is also available as triplex. A more limited range of sizes is available according to DIN 8188.