Ready-to-Install Sprockets

Easy installation, minimal downtime, no machining. Or will you choose another? We've updated the sprockets category in our Eshop.

- Do You Need Sprockets That Are Ready to Use Immediately?

- Special Sprockets: With Finished Bore, Hub, and Hardened Teeth

- Taper Lock Sprockets: A Flexible and Universal Solution

- Updated Sprocket Offering at TYMA CZ

Do You Need Sprockets That Are Ready to Use Immediately?

Whether you lack the time or resources for the lengthy production of a key component from a semi-finished product, ready-made sprockets are the ideal solution for you. They are prepared for immediate installation without the need for additional machining.

The standard range is designed for drives with all types of roller chains of the so-called European series (B series), standardized according to ISO 606 (DIN 8187). Only high-quality carbon steels are used in production, ensuring high strength and reliability.

Ready-Made Sprockets in the TYMA CZ Eshop

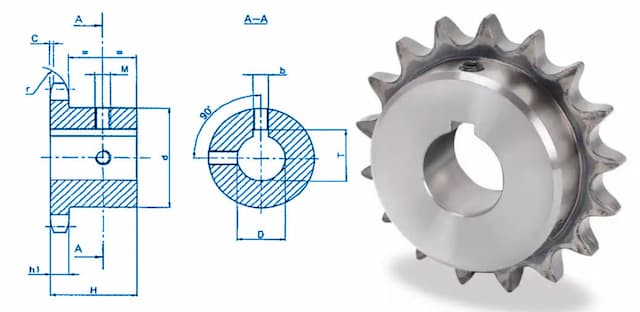

In the TYMA CZ Eshop and our data sheets, sprockets with a finished bore, hub, and hardened teeth are designated in the name with the abbreviation NKZ/D.

Will you choose sprockets with a finished bore, hub, and hardened teeth, or do you prefer the more flexible Taper Lock bushes solution? Both variants offer easy installation, reliability, and top precision in manufacturing. Let's take a closer look at them.

Special Sprockets: With Finished Bore, Hub, and Hardened Teeth

The design is engineered for easy and highly precise installation while ensuring maximum strength, long service life, and reliability, even in demanding operations requiring high performance intensity.

We offer sprockets with a finished bore, hub, and hardened teeth as standard in a single-strand design (simplex) for the most common chain pitches and tooth counts:

Table Showing the Basic Parameters of Standard Ready-Made Sprockets

| Type (ISO 606) | Pitch × Inner Chain Width | Number of Teeth |

|---|---|---|

| 06B | 3/8″ × 7/32″ | 10–30 |

| 08B | 1/2″ × 5/16″ | 10–30 |

| 10B | 5/8″ × 3/8″ | 10–25 |

| 12B | 3/4″ × 7/16″ | 10–25 |

| 16B | 1″ × 17,02 mm | 11–25 |

| 20B | 1 1/4″ × 3/4″ | 9–20 |

For each combination of pitch and number of teeth, we offer a sufficient range of bore diameters D to select the optimal and truly ready-made solution for any common application.

Let's examine the construction of these special sprockets in more detail.

Finished Bore

The bore is machined directly by the manufacturer with H7 tolerance.

For each sprocket type based on chain pitch and number of teeth, we offer variants with different bore diameters D. These dimensions are provided in mm and included in the product names in our Eshop, making it easy to select the right sprocket for your machine.

Keyway

The bore with a keyway ensures precise mounting and guarantees efficient power transmission between the chain and shaft.

The keyway, machined with P9 tolerance (according to DIN 6885/1), is positioned to align with the center of the tooth, allowing paired sprocket mounting.

Threads with Set Screws

The sprocket hub is equipped with two threaded holes and set screws for precise shaft fixation. One thread is aligned with the keyway, while the other is offset by 90°.

Hardened Teeth

Our ready-made sprockets are manufactured using high-quality, heat-treatable structural C45E steel (according to UNI EN 10083-1), which provides exceptional strength, hardness, and wear resistance, even under intensive loads. This makes them ideal for applications requiring precise power transmission.

All sprockets have induction-hardened teeth with a hardness of 45–55 HRC.

Finished Sprockets in the TYMA CZ Eshop

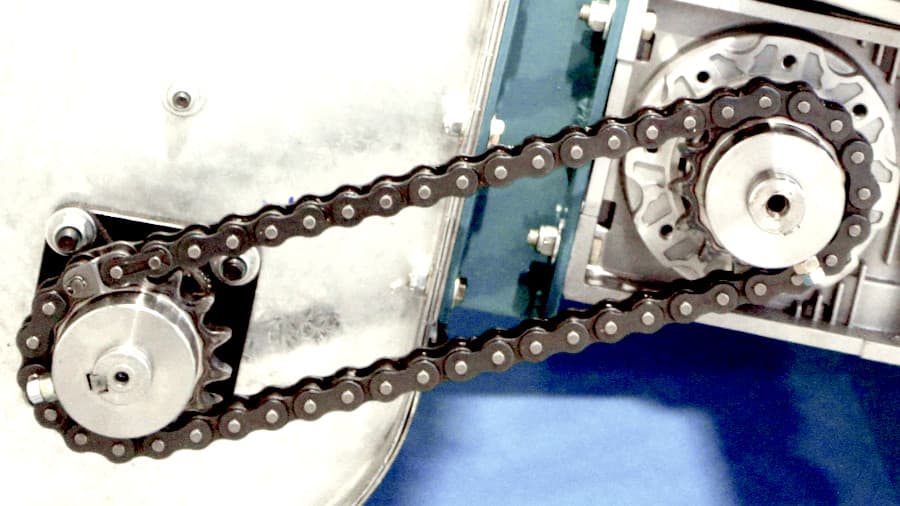

Taper Lock Sprockets: A Flexible and Universal Solution

Sprockets designed for mounting with Taper Lock tapered bushes offer additional construction variants.

Our range includes basic sprockets with standard teeth, versions with hardened teeth, and double sprockets for two single-strand chains (so-called double-single design).

-

Taper Lock Sprockets with Non-Hardened Teeth

Available as standard for 06B, 08B, 10B, 12B, 16B, 20B, and 24B roller chains (according to ISO 606). They are available in simplex, duplex, and triplex designs. These sprockets are designated by the simple abbreviation T (previously TB).

-

Taper Lock Sprockets with Hardened Teeth

Available as standard for 06B, 08B, 10B, 12B, 16B, and 20B roller chains (according to ISO 606). These are simplex sprockets. In our materials, they are designated by the abbreviation TK.

-

Taper Lock Double-Single Sprockets for Two Simplex Roller Chains

Designed for roller drives and conveyor systems with 06B, 08B, 10B, 12B, or 16B chains (according to ISO 606). They are designated by the abbreviation DT.

They are manufactured from high-quality carbon steel that meets strict durability requirements, mostly C43 steel, while some types are made from grey cast iron, such as EN-GJL-250 (according to UNI EN 1561).

Taper Lock sprockets allow for similarly easy, fast, and precise mounting onto the shaft without additional machining, just like special monolithic finished sprockets. Our Eshop offers standard Taper Lock bushes in many sizes, covering a wide range of bore diameters. From this perspective, Taper Lock sprockets are more universal, versatile, and even more flexible.

However, Taper Lock sprockets are not ideal for drives with extreme loads and shocks. This aspect should always be considered when selecting the right solution.

Taper Lock Bushes

Taper Lock bushes have a tapered outer surface and a cylindrical inner bore with H7 tolerance and a standardized keyway. Once installed and tightened with clamping screws, they reliably transmit torque and prevent axial movement. They are manufactured primarily from grey cast iron GG 20, with some versions also available in steel.

These bushes are independent components and are not included in the Taper Lock sprocket package.

Taper Lock Bushes in the TYMA CZ Eshop

Updated Sprocket Offering at TYMA CZ

In recent months, we have focused more on the sprocket assortment in our Eshop. We have also prepared new data sheets.

We have added new sprocket sizes and introduced entire new categories. Some have been consolidated. Cast iron sprockets are no longer in a separate category but are now classified based on their construction.

The new classification of sprockets corresponds to their design and functional use:

Sprockets for B Series Chains (according to DIN 8187)

-

Plate Wheels without Hub

In our Eshop and data sheets, designated with the abbreviation P. -

With Hub

In our Eshop and data sheets, designated with the abbreviation N. -

With Hub and Hardened Teeth

In our Eshop and data sheets, designated with the abbreviation NK. -

With Finished Bore, Hub, and Hardened Teeth

In our Eshop and data sheets, designated with the abbreviation NKZ/D. -

For Taper Lock Bushes

In our Eshop and data sheets, designated with the abbreviation T (previously TB). -

For Taper Lock Bushes with Hardened Teeth

In our Eshop and data sheets, designated with the abbreviation TK. -

Double-Single for 2 Chains

In our Eshop and data sheets, designated with the abbreviation D (previously DS). -

Double-Single for 2 Chains and Taper Lock Bushes

In our Eshop and data sheets, designated with the abbreviation DT. -

Stainless Steel with Hub

In our Eshop and data sheets, designated with the abbreviation N-SS.

Sprockets for A Series Chains (according to DIN 8188)

-

Standard Types and Designs – inquiry-based ordering.

For all other specific requirements, we offer custom-made sprockets. Feel free to contact us even in such cases.