SOLIFLEX Conveyor Belts for Perfect Hygienic Solutions

Homogeneous belts stand out for their easy maintenance, high resistance to cleaning agents and adherence to strict hygiene standards.

The homogeneous thermoplastic material prevents belt fraying, reducing the risk of food contamination. The blue color enhances safety in food applications.

SOLIFLEX belts are primarily used in the processing of meat, poultry, fish, vegetables, and also in bakeries, dairies, freezing plants, and other food production environments. They fully comply with international food hygiene standards.

They can be installed on existing conveyors, and with the appropriate conveyor design, automated cleaning can be done directly on-site.

SOLIFLEX Homogeneous Belts in the TYMA CZ Eshop

We are an authorized regional distributor of Ammeraal Beltech. Inquire about the belts via the inquiry form provided here. Then we will contact you and, if necessary, specify all the technical parameters and tell you the price of a specific product.

SOLIFLEX = SOLID & FLEXIBLE

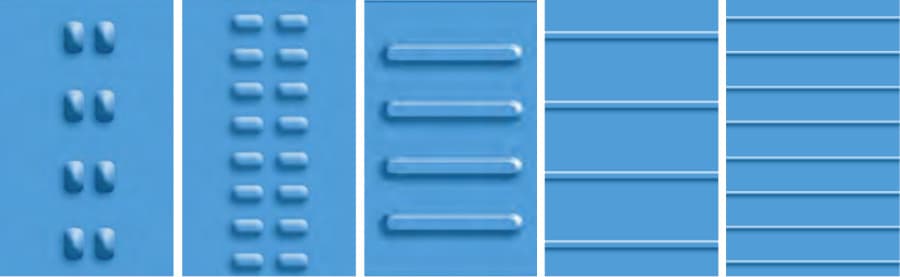

SOLIFLEX belts feature a completely smooth homogeneous surface with no gaps where bacteria could hide. They have no textile reinforcement. On the underside, regular protrusions fit precisely into drive and guiding wheels.

The solution can be adapted to the specific needs of each operation, whether for joint design, guidance, or equipping the conveyor with compatible accessories.

SOLIFLEX Belts Accessories

The SOLIFLEX guidance system is designed for easy and fast cleaning, with minimal water and cleaning agent consumption. As standard SOLIFLEX accessories, we offer sidewalls and transverse cleats in various shapes. They are made from the same material as the SOLIFLEX belts – from polyurethane.

In the food industry, scrapers are highly sought after since even non-stick belts can retain food residues.

ULTRASCRAPER scrapers by Ammeraal Beltech are made from high-quality co-extruded materials. To ensure maximum safety, they are detectable by metal detectors. The application of silver ions gives them antimicrobial properties. Their cleaning efficiency is enhanced by the soft cleaning edge tailored to the belt's hardness.

Conveyor Belt Cleaning in the Food Industry: Key to Hygiene and Safety

A clean conveyor belt not only protects products from contamination but also extends equipment life and ensures smooth operation. How can you properly care for a conveyor belt to meet all hygiene requirements?

The Importance of Regular Maintenance

Caring for belt cleanliness is absolutely crucial. It not only helps maintain equipment in good condition but, above all, protects product quality. In the food industry, even minor contamination can pose health risks to consumers, which is unacceptable. Regular and properly performed sanitation and disinfection at appropriate intervals reduce the risk of pathogen spread and ensure that all products meet strict hygiene standards.

Another benefit is increased operational efficiency. A dirty belt can slow down the production process due to friction, slippage, or improper guidance and cause costly downtime. Improperly sanitized or disinfected belts can ultimately lead to product recalls and damage a company's reputation. A properly maintained belt, on the other hand, enables smooth operation without downtime and reduces repair costs.

Cleaning, Sanitation, and Disinfection: What's the Difference?

To properly understand the issue, it is necessary to distinguish between cleaning, sanitation, and disinfection. Cleaning involves the removal of dirt, such as grime or product residues. Sanitation reduces the number of microorganisms to a safe level using sanitizing agents, while disinfection completely eliminates pathogens, including their spores.

These processes follow one another – without thorough cleaning, effective sanitation or disinfection cannot be achieved..

Types of Sanitation Systems

In the food industry, belts can be cleaned manually or automatically. For smaller operations, manual cleaning may be sufficient, but automated systems are faster, more efficient, and allow for continuous operation. CIP systems (Clean-In-Place) for in-line cleaning allow for hygienic maintenance without the need to disassemble the belt. Stations can be equipped with dry brushes and scrapers, or nozzles for wet cleaning.

An example is the above-presented top-of-the-line ULTRASCRAPER scrapers from Ammeraal Beltech with antimicrobial properties that minimize the risk of contamination and ensure longer life of both the belts and the scrapers themselves.

How to Choose the Right Cleaning Agent?

Cleaning agents should be carefully selected based on the belt material and the type of product being conveyed. For greasy or sticky substances such as grease or starch, special cleaning agents must be used.

Automated mixing systems that prepare the correct mixtures of water and chemicals simplify the process and increase cleaning efficiency.

Sanitation Validation: A Guarantee of Quality

Sanitation validation is an important step in verifying that your conveyor belts have been properly cleaned and are ready for the next production cycle. This step involves testing and creating documentation confirming that the sanitation methods used effectively remove residues, bacteria, and other hazardous substances.

This process is key to complying with strict hygiene and safety standards, especially in the food industry. By ensuring adherence to hygiene standards, you protect not only your customers but also your company's reputation.