We’ve Expanded Our Range of STD/STS Timing Belts

What are their key features and applications? We’ll introduce the offerings from Bando and ContiTech, compare STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. and HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques.. What makes STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. stand out?

- Super Torque Belts: The Widest Range of Profiles

- Bando: The STS Guru

- ContiTech and the STD Profile

- Comparison of the Most Common Timing Belt Profiles: HTD and STD/STS

- History of Super Torque Belts

You’ve likely encountered timing belt profiles with an “S” in their designation. Whether referred to as STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds., STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications., or even STPDSuper Torque Positive Drive

STPD is an alternative designation for the STD/STS profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD and STPD profiles are compatible with each other and can be used in the same applications. by manufacturers, the profile size designation always begins with the letter S – for example, S8M, S3M, or the seemingly exotic S4.5M. Behind these designations lies a proven yet highly modern and widely adopted type of synchronous belt profile: Super Torque.

Super Torque Timing Belts in the TYMA CZ Eshop

We are an authorized distributor of leading STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profile belts manufacturers – Bando and ContiTech.

Super Torque Belts: The Widest Range of Profiles

They are a reliable solution for a wide variety of drive applications. Their versatility, high performance, and ease of use make them a popular choice among engineers and technicians. Moreover, these timing belts currently offer the widest range of profiles and dimensions available.

The involute tooth shape is the result of optimizing standard timing belt profiles (trapezoidal, HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques., and others). It is designed to provide a larger contact area with the pulley, enabling higher force transmission, more precise synchronization, and longer service life.

Key Advantages of Super Torque Belts (STD/STS)

At a glance, compared to other common timing belt profiles:

-

Higher Transmission Efficiency

More efficient power transmission than earlier profiles. -

Operation at Higher Speeds

Suitable for higher peripheral speeds than HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. belts. -

Precise Synchronization

Allows for high positioning accuracy. -

Reduced Vibrations and Quiet Operation

Minimization of the polygon effect. Lower vibrations and noise compared to HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. profiles. -

Compact Design

Ideal for applications with limited installation space. -

Extended Service Life

Improved load distribution on teeth and higher material quality. Reduced maintenance requirements. -

Versatility

Available in the widest range of profile sizes, widths, and belt lengths.

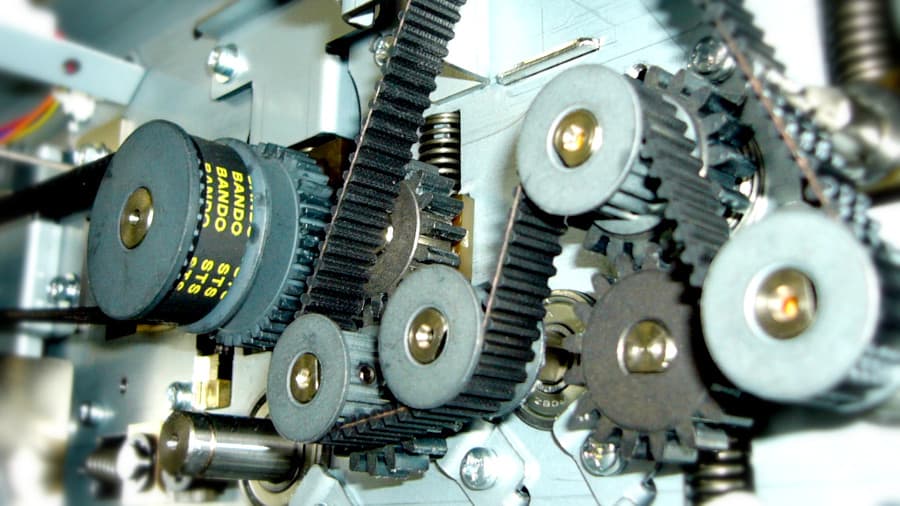

Where Can You Find Super Torque Belts?

Timing belts in STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profiles are increasingly used across various industries and applications thanks to their outstanding characteristics.

They are found in applications ranging from the automotive industry (camshaft drives, auxiliary drives) to general engineering (conveyors, packaging machines, textile machines, printing presses, pump drives, compressors, etc.) and agricultural applications (mower drives and other auxiliary synchronous drives) to larger and smaller office equipment or household appliances.

In the next section, we’ll take a closer look at the range of belts available in Super Torque profiles.

Bando: The STS Guru

STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. belts offer the widest range of profiles and dimensions. Bando utilizes the STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profile extensively across its entire timing belt portfolio.

The Super Torque profiles are typically found in machines and devices of Asian origin, or conversely, Asian-origin machines often use STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. belts. This is due to the history of the profile’s development and its adoption in the market, where the Japanese company Bando played a key role.

Bando refers to the profile as STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. (Super Torque Synchronous) and, like other manufacturers, offers its belts in various performance levels:

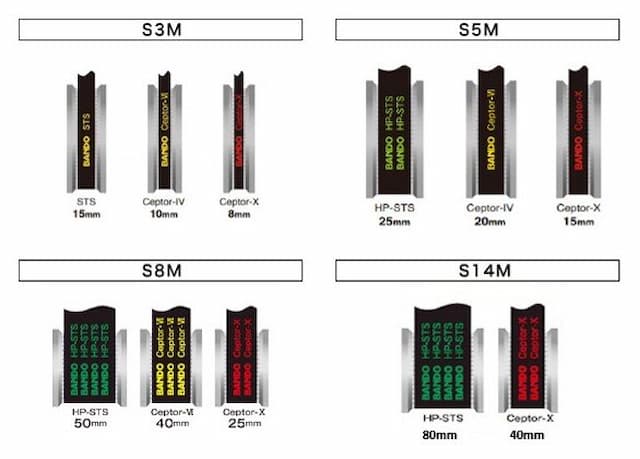

Standard Series: Bando STS

The standard series is simply labeled STS. These belts are identified by yellow markings on the back. They are designed for mainstream applications with high loads and speeds and provide all the benefits of the profile’s characteristics – especially precise and quiet operation, vibration damping, and long service life.

Bando HIGH PERFORMANCE

The HIGH PERFORMANCE (HP) series offers reinforced design. STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. belts in this series feature green markings with the label HP-STS. They provide a 1.4 to 1.8 times higher power transmission capacity compared to the standard STS series.

Bando CEPTOR

Bando CEPTOR-VI Bando CEPTOR-X

The most advanced rubber timing belts in the STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profile are branded as CEPTOR. Currently, there are two series available: the older CEPTOR-VI, with special glass-fiber tension member, and the state-of-the-art CEPTOR-X.

Top-quality CEPTOR-X belts are made of highly durable synthetic rubber HNBRHydrogenated Nitrile (Acrylonitrile) Butadiene Rubber (Hydrogenated Nitrile Butadiene Rubber), with carbon tension member. CEPTOR-X belts are identified by red markings. According to the manufacturer, they will gradually replace the older CEPTOR-VI series, which have yellow markings.

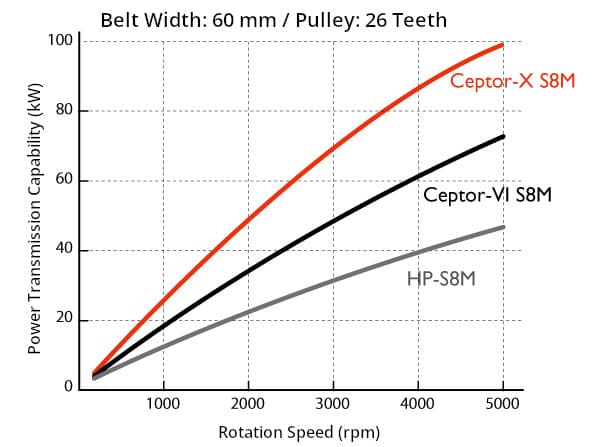

The optimized construction of higher-performance series enables narrower belts and pulleys, allowing compact and lightweight drive solutions. For example, CEPTOR-X belts can achieve the same power transmission at half the width compared to even the high-performance Bando HP-STS belts in certain profiles.

CLEAN Design

In some profiles, Bando timing belts feature a special impregnated fabric on the teeth, which further reduces operational noise and ensures smoother transmission. This technology is simply called CLEAN (or CLEAN TYPE).

Performance Categorization of Bando STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. Belts:

STS for Small and Miniature Drives

Rubber timing belts in the smallest STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profiles, S1.5M, S2M, and S3M, provide precise belt-to-pulley engagement, making them ideal for various precision small machines and devices, such as printers, 3D printers, copiers, and scanners.

The most advanced CEPTOR design is available starting from the S3M profile.

Medium-Power Applications and Unique S4.5M Profile

For medium-power applications, the S5M profile is used. Additionally, the unique S4.5M profile is often found in textile or machining equipment.

Like the smaller profiles, various performance levels are available here, from basic to HP-STS and the top-tier CEPTOR series.

Optimized Dimensions for High-Power Applications

For the highest power requirements, the S8M and S14M profiles are used. These are also available in all performance levels.

In the case of the S8M and S14M profiles, the basic Bando STS belts are now considered phased-out products. The new standard will be HP-STS belts, featuring reinforced fibers and offering 25% to 30% higher power transmission.

Even in these profiles, the most advanced options include belts with carbon fibers, such as CEPTOR-X.

STS as Double-Sided Belts

Most profiles and dimensions are also available as double-sided belts. These belts from Bando are straightforwardly labeled as Double-Sided STS.

Standard STS Belts in the TYMA CZ Eshop

Bando HP Belts in the TYMA CZ Eshop

Bando CEPTOR Belts in the TYMA CZ Eshop

Double-Sided STS Timing Belts in the TYMA CZ Eshop

ContiTech and the STD Profile

One of the leading European manufacturers of drive belts in the Super Torque profile is Continental ContiTech, which primarily produces these belts in the STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. S8M profile.

ContiTech refers to this profile as STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds. (Super Torque Drive) and offers S8M profile belts in a wide range of performance options:

CONTI SYNCHROBELT

A standard version designed for powerful and reliable solutions across a broad range of performance needs.

CONTI SYNCHROFORCE CXP

Reinforced version for transmitting high power and achieving the highest peripheral speeds.

CONTI SYNCHROFORCE CXA

Reinforced version with aramid tension member and a special N-DURO rubber compound for transmitting the highest torques.

CONTI SYNCHROFORCE CARBON

The latest and most advanced version with carbon tension member, designed for high forces, acceleration, and shock loads.

CONTI SYNCHROTWIN as Double-Sided Super Torque

ContiTech labels double-sided timing belts in Super Torque profiles with the abbreviation DSTDDouble-Sided Super Torque Drive

Thanks to its involute-shaped geometry, the STD profile achieves optimal meshing of the teeth in the sprocket. As a result, the STD also ensures very precise, low-noise operation even at high belt speeds. The profile is also available in the double-sided DSTD version.. The profile size designation begins with the letters DS (e.g., DS8M).

These belts are available both in the standard CONTI SYNCHROTWIN version and in the reinforced CONTI SYNCHROTWIN CXP version.

CONTI SYNCHROBELT S8M Belts in the TYMA CZ Eshop

CONTI SYNCHROFORCE CXP S8M Belts in the TYMA CZ Eshop

CONTI SYNCHROFORCE CXA S8M Belts in the TYMA CZ Eshop

CONTI SYNCHROFORCE CARBON S8M Belts in the TYMA CZ Eshop

CONTI SYNCHROTWIN CXP DS8M Belts in the TYMA CZ Eshop

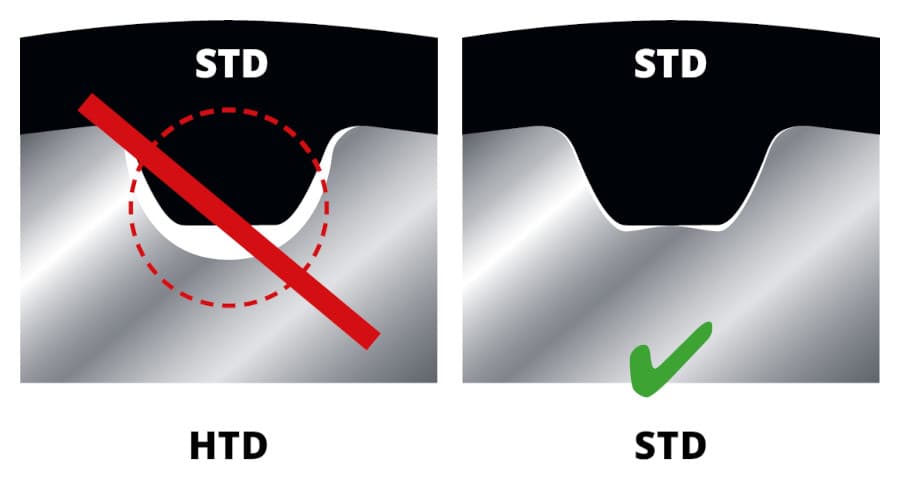

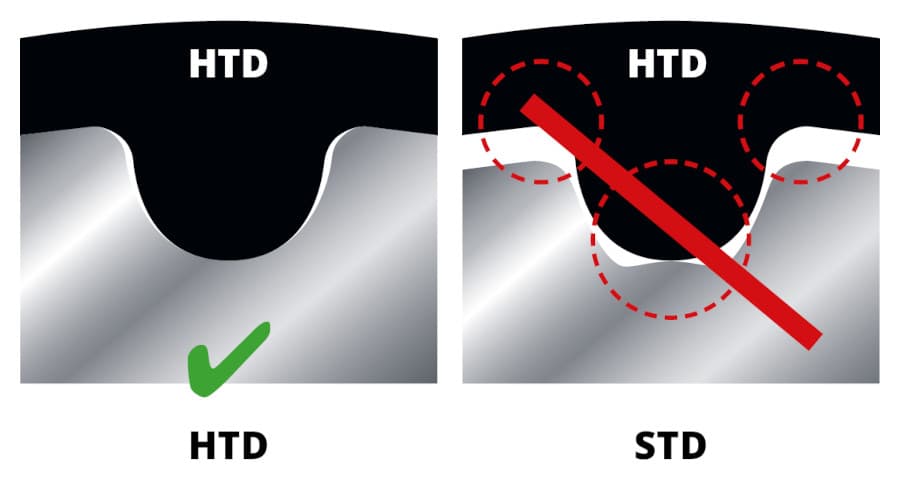

Comparison of the Most Common Timing Belt Profiles: HTD and STD/STS

HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. profiles are suitable for transmitting high torque. These are the most widely used tooth profiles for industrial timing belts. Thanks to their tooth height and semi-circular shape, they ensure particularly high resistance to tooth skipping during operation.

As we have already described, STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profiles provide additional smooth and quiet operation, even at high belt speeds. These properties are achieved due to the involute tooth shape and their optimal engagement with the pulley.

Super Torque Profiles Offer High Positioning Accuracy

One of the advantages of STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profiles is their high positioning accuracy. However, this must result from the correct alignment of the timing belt and the pulley.

The STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profile, unlike HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. profiles, allows the creation of a drive system with reduced tooth backlash, down to zero backlash of the pulley profile. Such a system achieves maximum precision.

In these specific cases, technical consultation is necessary. The proper functionality of a reduced or zero-backlash drive system depends on many factors, such as tensioning force, the number of teeth engaged, load parameters (speed, torque, shocks, etc.), pitch size, belt tolerances, and pulley tolerances.

Request a Technical Consultation

The HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. profile has a circular tooth shape, making backlash reduction by modifying the pulley tooth profile impossible. The belt tooth would not fit into the tooth gap, leading to excessive wear.

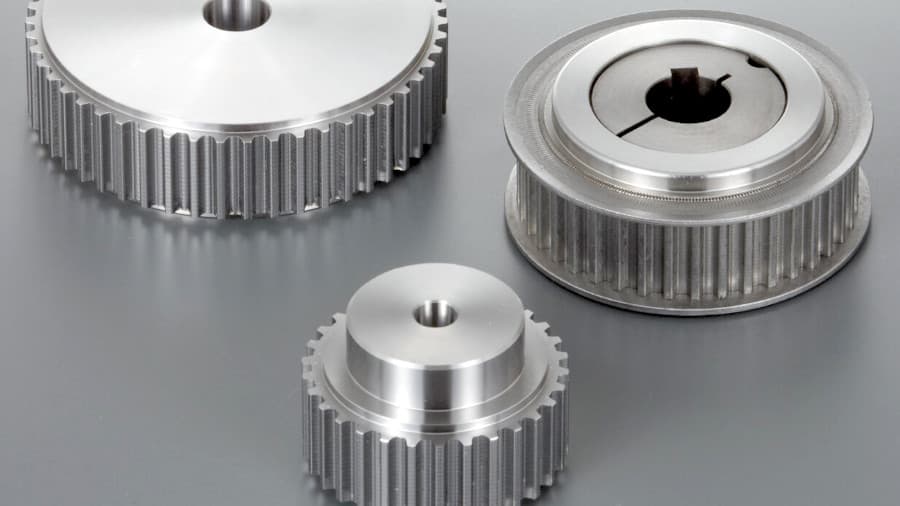

Mind the Pulleys

The STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. and HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques. profiles share many similar properties. However, it is crucial to use the correct type of pulley.

Attention: It is essential to always use the correct type of pulley for STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. or HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques.!

As shown in the images above, the pulley profiles are not interchangeable. Using an incorrect pulley will quickly damage the belt. In many cases, it may even be impossible to mount the belt onto the pulley.

Standard STD/STS Pulleys in the TYMA CZ Eshop

STD/STS Pulleys for Taper Lock Bushes in the TYMA CZ Eshop

History of Super Torque Belts

Since the 1990s, the STDSuper Torque Drive

The involute shape of the STD profile allows optimal tooth engagement with the pulley. As a result, it provides precise and quiet operation even at high belt speeds./STSSuper Torque Synchronous

STS is an alternative designation for the STD profile used by some manufacturers. Its involute shape allows optimal tooth engagement with the pulley, ensuring precise and quiet operation even at high belt speeds.

The STS, STD or even STPD profiles are compatible with each other and can be used in the same applications. profile has become a new standard not only in the automotive industry but also in many industrial and consumer applications.

The timing belt was originally developed in the USA and reached Europe in the 1960s. The first known application dates back to 1962, when it was installed in the Glas 1004, a West German car (engine with a displacement of 992 cm3 and an output of 42 HP). It was one of the most advanced production engine designs of its time. It was the first to use a timing belt for valve control instead of a traditional chain, significantly improving efficiency and reducing valve drive noise, making it remarkably ahead of its time.

Belts with trapezoidal profiles (e.g., MXL, XL, T2.5, T5) soon gained considerable popularity in industrial applications. In the 1970s, a major advancement occurred with the introduction of the High Torque profile (HTDHigh Torque Drive

Because of its tooth height and semi-circular tooth geometry, the HTD profile is especially good at avoiding jump-over of the teeth in operation. The HTD profile is extremely suitable for transmitting high torques., HTSHigh Torque Synchronous

, etc.). This profile, with its semi-circular tooth geometry, offered better power transmission and reliability.

However, by the 1980s, the automotive industry began adopting an even more advanced profile – Super Torque – which, thanks to its properties, continuous innovations, and improvements, remains widely used across industries to this day.