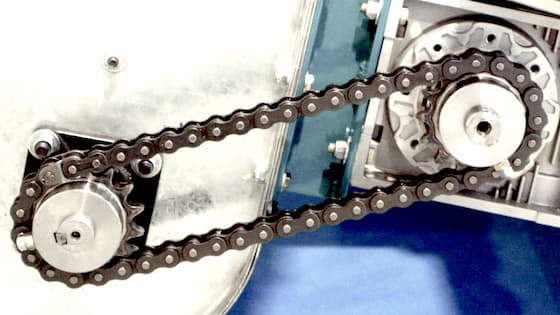

Sprockets with Finished Bore, Hub, and Hardened Teeth for DIN 8187 Roller Chains (B-Series)

B-series sprockets with finished bore, hub, and hardened teeth are ready for immediate installation on the appropriate shaft without the need for additional machining. They are designed for drives with all types of roller chains of the so-called European series (B-series), standardized to ISO 606 (DIN 8187). They are available in simplex design.

06B (3/8″ × 7/32″)

08B (1/2″ × 5/16″)

10B (5/8″ × 3/8″)

12B (3/4″ × 7/16″)

16B (1″ × 17.02 mm)

20B (1 1/4″ × 3/4″)

Typical Applications

Sprockets with a finished bore, hub, and hardened teeth for DIN 8187 roller chains are designed for a wide range of industrial applications – from light to heavy industry.

They are most commonly used in power transmission systems, but they also find applications in lifting and material transport systems. Typical fields of use include conveyors, food processing machines, and glassmaking equipment, as well as many other industrial applications.

Materials

C45E steel (according to UNI EN 10083-1).

Sprocket Code Description

Example:

08B-1-12-NKZ/D24 (1/2″ × 5/16″) - 12 Teeth, with Hub, Hardened Teeth, 2 Screws, Bore 24H7, Keyway (Steel)

| Code Part | Description |

|---|---|

| 08B |

Chain type |

| 1 |

Simplex design |

| 12 |

Number of teeth |

| NKZ/D |

Design with hub, hardened teeth, 2 threads with screws, and finished bore |

| 24 |

Finished bore diameter (in mm) |

| 1/2″ × 5/16″ |

Pitch (in inches) × inner width (in inches) |

| 12 Teeth, with Hub, Hardened Teeth, 2 Screws, Bore 24H7, Keyway (Steel) |

Sprocket design, finished bore diameter (in mm) with tolerance field, and sprocket material |

Documents for Download

Dimensions and Parameters of Hardened Teeth Sprockets with Finished Bore

TYMA CZ Data Sheets

Czech and English (PDF 1.39 MB)