Bando BANCOLLAN TN Timing Belts

Bando BANCOLLAN timing belts in triangular TN profiles are designed for highly precise and stable transmission in low to medium power ranges, with high torque and at both low and high speeds. The triangular tooth profile ensures backlash-free contact between the belt and pulley, while the small pitch provides rotation smoothness similar to flat belts.

The belts are made from a special BANCOLLAN polyurethane compound and polyester or aramid fiber tension member. They allow long-term, maintenance-free operation in miniature and very small transmissions, meeting demands for high transmission capacity, precision, and cleanliness.

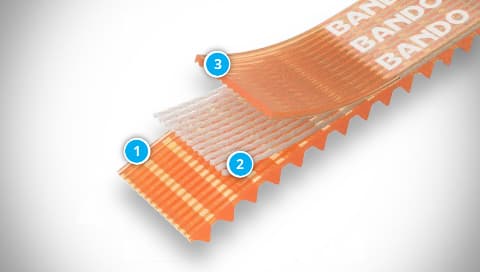

Belt Construction

- Polyurethane teeth

- Polyester or aramid tension member

- Polyurethane backing

Typical Applications

Bando BANCOLLAN polyurethane timing belts provide reliable solutions for very low, low, and medium power ranges across various applications.

They are typically used in machines and devices ranging from the smallest, miniature equipment such as printers, copiers, 3D printers, plotters, cameras, ATMs, optical devices, kitchen appliances, hand tools, industrial manipulators, and robots, among many others.

Their use is particularly advantageous in applications where oil from technological processes, transmissions, or bearings may affect belt properties (e.g., machining tools or gearboxes), in applications that generate ozone during operation (e.g., optical devices and copiers), or in applications requiring clean power transmission. The belts are suitable for laboratory and medical devices, as well as food processing and packaging machines.

Properties

- Highly precise synchronous operation with minimal backlash

- Very high belt flexibility and durability

- Smooth rotation due to small pitch (close to the rotation of flat belts but with precise revolutions)

- High dimensional and shape stability

- Temperature resistance from −30 °C to +70 °C

- Maintenance-free

- Very clean operation (no small particles or dust released like with rubber belts)

- Resistance to oils, greases, acids, and alkalis

- Resistance to ozone

Belt Code Description

Example:

5 TN15 - 270 BANCOLLAN (180 TN15-5.0 K)

The first part represents the standard belt marking system we use across all manufacturers:

| Code Part | Description |

|---|---|

| 5 |

Belt width in mm |

| TN15 |

Profile and pitch in tenths of mm (15 × 1/10 = 1.5 mm) |

| 270 |

Belt length in mm |

| BANCOLLAN |

Belt type |

The marking inside the parentheses corresponds to the manufacturer's catalog:

| Code Part | Description |

|---|---|

| 180 |

Number of teeth |

| TN15 |

Profile and pitch in tenths of mm (15 × 1/10 = 1.5 mm) |

| 5.0 |

Belt width in mm |

| K |

Symbol for tension member material: |

Documents for Download

Belt Manufacturer Profile

Japanese company Bando has been a pioneer in the non-tire rubber and plastics industries since their founding in 1906, responding to customer needs with new technology and product development.

Over the years Bando have expanded upon their core business to meet the ever-changing needs of the times, and they now produce a wide range of products. They now serve their customers worldwide from more than 10 countries in Asia, North America and Europe.