Bando CEPTOR-X Heavy-Duty Timing Belts

Reinforced Bando CEPTOR-X (CEPTOR-10) timing belts in the STD (STS) profile are designed for the highest power transmission, torque, and high speeds.

The belts are made from an exceptionally durable HNBR synthetic rubber compound with carbon fiber tension members and teeth protected by impregnated fabric on the surface. They allow long-term, maintenance-free operation even in demanding applications with high power transmission. Even at high speeds, they effectively reduce vibrations and noise. The optimized design enables narrower belt and pulley widths for compact and lightweight drive solutions.

CEPTOR-X STD S14M (STS S14M)

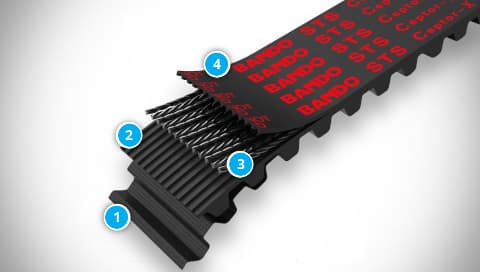

Belt Construction

- Special nylon fabric

- HNBR synthetic rubber teeth

- Carbon tension member

- HNBR synthetic rubber backing

Typical Applications

Bando CEPTOR-X are rubber timing belts providing reliable solutions even in high-performance transmissions across most industrial areas.

They are typically used in textile machines, machine tools, presses, printing machines, industrial printers, 3D printers, scanners, and many other machines in various industries.

Properties

- Highest power transmission

- Excellent tensile stability

- High reliability and long service life

- Low noise level

- Vibration damping

- Optimized belt and pulley width (half the width compared to Bando HP-STS high-performance belts)

- Compatibility with standard pulleys in the STD profile

Belt Code Description

Example:

STD S8M-1000-60 CEPTOR-X (STS 600 CEPTOR-X S8M 1000)

The first part represents the standard belt marking system we use across all manufacturers:

| Code Part | Description |

|---|---|

| STD |

Belt profile |

| S8M |

Tooth pitch in mm |

| 1000 |

Belt length in mm |

| 60 |

Belt width in mm |

| CEPTOR-X |

Belt type |

The marking inside the parentheses corresponds to the manufacturer's catalog:

| Code Part | Description |

|---|---|

| STS |

Belt profile name according to Bando |

| 600 |

Belt width in tenths of mm (600 × 1/10 = 60.0 mm) |

| CEPTOR-X |

Belt type |

| S8M |

Tooth pitch in mm |

| 1000 |

Belt length in mm |

Documents for Download

Belt Manufacturer Profile

Japanese company Bando has been a pioneer in the non-tire rubber and plastics industries since their founding in 1906, responding to customer needs with new technology and product development.

Over the years Bando have expanded upon their core business to meet the ever-changing needs of the times, and they now produce a wide range of products. They now serve their customers worldwide from more than 10 countries in Asia, North America and Europe.